327 voie romaine - 24100 LEMBRAS [France]

419 262 886 R.C.S. BERGERAC

☎ +33(0)5 53 22 82 36 ✉ info@coda.tepex.eu

Other site : www.coda.tepex-blasting.com

A - Establish the forehead profile

All profiles are linked to a reference level (reference line). On this line, choose a characteristic point of the face or position a reference point. This point will be the « reference » for the profiling performed on each of the holes in the firing plan.

1/ Aim the reference.

2/ Aim the top of the face.

3/ Aim for points from the top to the base of the forehead.

A measurement is recorded by pressing the appropriate button on the laser profiler. The tablet, in Bluetooth connection with the latter, stores the coordinates of each target point for which a measurement is requested.

The accuracy of the profile displayed on the tablet depends on the number of points recorded (150 maximum)..

B - Implant the borehole

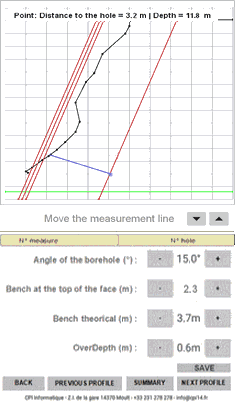

Depending on the profile obtained, the operator can adjust, at the foot of the face, the borehole implantation. It can modify the theorical bench, the bench at the top of the front (distance between the front and the front), the drilling angle and the over-depth by pressing the - or + keys located on either side of the displayed values (see Screen 1 opposite : variation of the hole-front distance).

Clicking on the screen shows a blue line between the profile and the hole. The width of the bench and the depth (or length) of the hole at this point are indicated at the top of the screen (see Screen 2 opposite). ▼ und ▲ keys make it possible to move the measurement line over short distances.

Screen 1

Screen 2

C - Exploit the results

Saved files are editable.

The information collected on the career can be transferred from the tablet to a computer (PC) using the USB cable provided (see point V of the user manual of the profiler).

An automatic report, in « pdf » format, containing the drilling characteristics can be printed and communicated to the driller to enable him to optimally locate the drill holes.

This report can be kept as a record for quality assurance purposes.

Publication director : Eric WARTELLE • Hosting : OVH - 59100 Roubaix [France] • Last update : 27/09/2021

Publication director : Eric WARTELLE

Hosting : OVH - 59100 Roubaix [France]

Last update : 27/09/2021

© 2007-2021 • TEPEX the straight burden checker